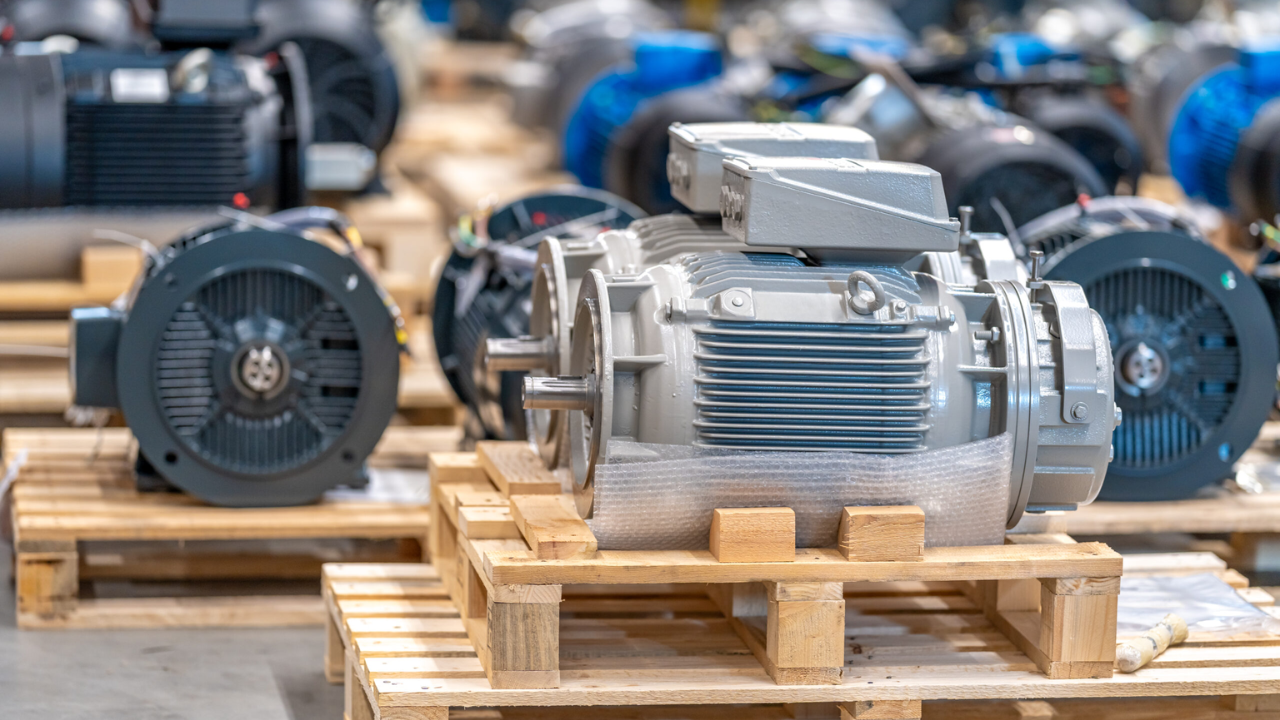

What Professionals Should Know About Choosing Electric Motors for Their Projects

2024-12-08

Choosing the right electric motor is vital because it directly affects the efficiency, performance, and reliability of a project. A well-selected motor ensures optimal power delivery, reduces energy consumption, and minimizes maintenance costs.

Incorrect motor selection can lead to inefficiencies, overheating, and premature failure, potentially causing costly downtime. By carefully matching motor specifications to the application’s load, speed, and environmental demands, professionals can enhance project longevity, safety, and overall success.

Factors to Consider When Choosing an Electric Motor for Your Facility

When selecting an electric motor, understanding key specifications is essential to ensure optimal performance and compatibility with your project. Here are the primary specifications to consider:

1. Power Rating (Horsepower or Kilowatts)

The power rating defines the motor’s capacity to perform work. Choosing the correct power rating is crucial to meet your project’s demands without overloading or underpowering the motor. Under-sizing can lead to inefficiency and overheating, while over-sizing increases costs unnecessarily. Calculating the required power based on load and application is essential for optimal performance.

2.Torque and Speed (RPM)

Torque measures the motor's rotational force, while speed, typically measured in revolutions per minute (RPM), indicates how fast the motor runs. Different applications require varying torque and speed combinations. For instance, high-torque, low-speed motors are ideal for heavy lifting, while high-speed motors suit applications like fans or pumps. Understanding the torque-speed relationship helps ensure the motor matches your project's mechanical requirements.

3. Service Factor

- The service factor is a multiplier that shows how much overload a motor can handle beyond its rated capacity. For instance, a service factor of 1.2 means the motor can safely operate at 120% of its rated load. A higher service factor is desirable in applications prone to load fluctuations, ensuring motor durability and preventing overheating or failure.

4. Efficiency Rating

Motor efficiency reflects how effectively electrical energy is converted into mechanical energy. Motors with high efficiency ratings, such as those with IE2 & IE3 ratings, can reduce energy consumption, lower operating costs, and decrease heat generation, especially in continuous-use applications. Opting for energy-efficient motors also contributes to sustainability goals.

5. Duty Cycle

The duty cycle indicates how long a motor can operate before it needs to cool down. Motors used for intermittent or stop-start operations need a duty cycle rating that matches their intended usage. Continuous-duty motors are designed for constant operation, while intermittent-duty motors are meant for short, periodic use.

6. Voltage and Current

Matching the motor’s voltage and current requirements to your power supply is critical to avoid electrical issues. Motors are designed to operate within specific voltage ranges, and exceeding these can cause damage. Proper alignment ensures efficient operation and prevents overheating or electrical failures.

What Should You Consider for When Purchasing Electric Motors?

When purchasing electric motors, several key factors should be considered to ensure the motor meets the specific needs of your project. First, determine the motor type (AC or DC) based on the application's requirements for speed, torque, and control.

Next, assess the power rating (horsepower or kilowatts) to ensure the motor can handle the load and avoid under- or over-sizing. Consider the torque and speed specifications, as different applications require different torque-speed combinations.

You should also take into account the efficiency rating to optimize energy consumption and reduce long-term operating costs. Additionally, examine the environmental conditions such as temperature, humidity, and exposure to dust or chemicals, as these will influence the motor’s durability and required protection (IP rating or hazardous area certifications).

Finally, factor in maintenance needs and service life by ensuring the motor is easy to maintain, has adequate warranties, and comes from a reliable manufacturer that offers strong technical support.

These considerations will help ensure that you choose a motor that not only meets performance demands but also provides long-term reliability and cost-effectiveness.

Conclusion

Choosing the right electric motor for a project is a critical decision that impacts performance, efficiency, and overall success. Professionals must carefully consider factors such as motor type, power rating, torque, speed, and environmental conditions to ensure the motor meets the specific demands of the application.

By understanding key motor specifications and aligning them with project needs, you can enhance operational efficiency, reduce energy consumption, and extend the lifespan of the motor.

Ultimately, a well-informed motor selection not only improves the reliability of your project but also minimizes long-term costs and downtime, contributing to a more efficient and sustainable operation.

Search

Recent Post

-

How industrial pump suppliers ensure efficiency and longevity of equipment

Industrial pumps play a critical role in manufacturing, processing, and large-scale production. The efficiency and lifespan of these essential machines depend heavily on the quality of the pump and the support provided by the supplier.

A reliable supplier ensures that the right pump is selected, installed, and maintained properly for optimal performance and durability.

In this guide, we’ll explore how industrial pump suppliers like Calama Pumps contribute to equipment efficiency and longevity.

Understanding the Importance of Industrial Pump Efficiency and Longevity

Efficient industrial pumps reduce operational costs, minimize downtime, and enhance productivity. Longevity ensures fewer replacements and repairs, leading to long-term savings and consistent performance. High-quality suppliers prioritize both efficiency and durability to maximize the value of their products.

How Industrial Pump Suppliers Ensure Efficiency

1. Providing High-Quality Pumps

A top-tier supplier offers pumps made from durable, corrosion-resistant materials designed to handle various industrial fluids and pressures. Calama Pumps, for instance, provides robust equipment built for demanding environments.

2. Expert Consultation and Product Selection

Proper pump selection is crucial for efficiency. Suppliers assess your system’s requirements, including flow rate, pressure, and fluid type, to recommend the ideal pump model.

3. Customization Options

Some industrial applications require tailored solutions. Reliable suppliers offer customization, ensuring pumps are designed to meet specific operational needs.

4. Advanced Technology and Innovation

Modern industrial pumps feature advanced designs that improve efficiency, such as variable frequency drives (VFDs) and high-efficiency impellers. Suppliers stay updated with technological advancements to offer cutting-edge products.

5. Energy Efficiency Focus

Energy-efficient pumps lower operational costs and reduce environmental impact. Suppliers guide businesses toward models with high-efficiency ratings and optimized performance.

How Industrial Pump Suppliers Ensure Longevity

1. Quality Assurance and Testing

Reputable suppliers conduct rigorous testing to ensure their pumps meet industry standards for performance and durability.

2. Comprehensive Installation Support

Proper installation is key to longevity. Suppliers provide detailed guidance and professional installation services to prevent common issues.

3. Maintenance and Service Plans

Regular maintenance extends pump life. Suppliers like Calama Pumps offer service packages, including inspections, part replacements, and performance assessments.

4. Access to Genuine Spare Parts

Using authentic parts ensures compatibility and maintains performance. Established suppliers stock a wide range of genuine components.

5. Training and Technical Support

Knowledgeable operators enhance efficiency and lifespan. Suppliers provide training programs and ongoing technical support to keep systems running smoothly.

Why Choose Calama Pumps for Industrial Solutions

Calama Pumps stands out as a trusted name in the industry, offering high-quality pumps, expert consultation, and comprehensive after-sales support. Their commitment to efficiency and longevity makes them a preferred choice for industrial operations worldwide.

Frequently Asked Questions (FAQs)

Why is supplier selection important for pump efficiency?

The right supplier ensures you get high-quality, energy-efficient pumps tailored to your needs, reducing operational costs and enhancing performance.

How do industrial pump suppliers improve equipment longevity?

Suppliers offer quality products, proper installation, regular maintenance, and access to genuine parts, all of which extend pump life.

What role does customization play in pump efficiency?

Customized pumps match specific operational requirements, optimizing performance and minimizing wear and tear.

Why trust Calama Pumps for industrial solutions?

Calama Pumps provide durable, efficient equipment with excellent support services, ensuring long-term reliability and productivity.

How often should industrial pumps be serviced?

Regular maintenance, including inspections and part replacements, should be conducted at least annually to maintain efficiency and prevent breakdowns.

By partnering with reliable industrial pump suppliers like Calama Pumps, businesses ensure their equipment operates at peak efficiency and enjoys a long service life. Quality products, expert support, and comprehensive maintenance plans all contribute to optimal performance and cost savings over time.

-

High pressure pumps: how they work and where they are used

High-pressure pumps play a crucial role in various industrial and commercial operations. From manufacturing plants to water treatment facilities, these pumps ensure fluid movement under high pressure, enabling efficient processes and system performance.

In this detailed guide, we’ll dive into the working mechanisms of high-pressure pumps, their key applications, and why trusted suppliers like Calama Pumps offer some of the best solutions available.

Understanding High-Pressure Pumps

A high-pressure pump is designed to move liquids at significantly increased pressures compared to standard pumps. These pumps convert mechanical energy into hydraulic energy, generating pressure that propels fluid through pipelines and systems at high velocities.

Key Components of High-Pressure Pumps

- Pump Head: The part where the fluid enters and exits.

- Piston or Plunger: Moves back and forth to create pressure.

- Seals and Valves: Ensure fluid direction and prevent leaks.

- Motor: Provides the mechanical energy required to drive the pump.

Working Mechanism

High-pressure pumps operate by displacing a specific volume of fluid through the pump’s head using a piston, plunger, or rotating component. As the motor powers the movement, it creates pressure that pushes the liquid through the discharge line.

Types of High-Pressure Pumps

1. Reciprocating Pumps

Reciprocating pumps use pistons or plungers to displace fluid in a back-and-forth motion. These pumps are known for their precision and ability to handle high-viscosity fluids.

Applications:

- Oil and gas industry

- Chemical processing

- High-pressure cleaning systems

2. Centrifugal High-Pressure Pumps

Centrifugal pumps use rotating impellers to generate pressure through centrifugal force. They are ideal for moving large volumes of fluid quickly and efficiently.

Applications:

- Water supply systems

- HVAC systems

- Irrigation

3. Diaphragm Pumps

Diaphragm pumps use flexible membranes to create pressure without direct contact between the liquid and moving parts. This makes them suitable for handling corrosive and abrasive fluids.

Applications:

- Chemical transfer

- Food and beverage industry

- Pharmaceutical manufacturing

Key Applications of High-Pressure Pumps

1. Water Treatment Plants

High-pressure pumps help move water through filtration and purification systems, ensuring clean and safe water supply.

2. Manufacturing and Production

Industries rely on these pumps for cooling, lubrication, and fluid transfer processes that require consistent pressure.

3. Oil and Gas Sector

From drilling operations to pipeline transportation, high-pressure pumps manage fluid movement under extreme conditions.

4. Power Generation

In power plants, these pumps maintain cooling systems and steam production, essential for efficient energy generation.

5. Cleaning and Maintenance

High-pressure washers use these pumps for industrial cleaning, ensuring thorough removal of dirt and contaminants.

Factors to Consider When Choosing a High-Pressure Pump

1. Pressure and Flow Rate Requirements

Assess your system’s pressure needs and fluid volume to select a pump with the right capacity.

2. Fluid Type

Consider the chemical composition, temperature, and viscosity of the fluid being pumped.

3. Material and Durability

Choose pumps made from corrosion-resistant materials for longevity and reliability.

4. Energy Efficiency

Opt for high-efficiency models to reduce operational costs and environmental impact.

5. Supplier Reputation

Trusted suppliers like Calama Pumps provide high-quality equipment and expert support.

Why Calama Pumps Are a Trusted Choice

Calama Pumps have established themselves as industry leaders in providing high-performance high-pressure pumps. Known for their reliability and efficiency, Calama Pumps cater to diverse industrial needs with customized solutions and exceptional after-sales support.

Frequently Asked Questions (FAQs)

What industries use high-pressure pumps the most?

Industries like water treatment, oil and gas, manufacturing, and power generation rely heavily on high-pressure pumps.

How do high-pressure pumps differ from standard pumps?

High-pressure pumps generate significantly higher pressure, making them suitable for demanding applications.

Are high-pressure pumps energy-efficient?

Yes, modern high-pressure pumps are designed for efficiency, reducing energy consumption and operational costs.

How do I maintain a high-pressure pump?

Regular maintenance, including seal checks, lubrication, and part replacements, ensures optimal performance.

Why choose Calama Pumps for high-pressure solutions?

Calama Pumps offer durable, efficient, and customizable high-pressure pump systems with excellent support services.

High-pressure pumps are indispensable in industrial applications requiring reliable fluid movement and consistent pressure. By partnering with reputable suppliers like Calama Pumps, businesses ensure they receive top-quality equipment tailored to their operational needs.

-

Why centrifugal pumps are the most popular choice for industrial applications

Centrifugal pumps are widely regarded as the most popular and efficient solution for industrial applications worldwide. Their simplicity, versatility, and cost-effectiveness make them the go-to choice for industries ranging from manufacturing to chemical processing.

In this comprehensive guide, we’ll explore why centrifugal pumps are so favored and why trusted suppliers like Calama Pumps often recommend them for various industrial needs.

Understanding Centrifugal Pumps

A centrifugal pump uses rotational energy, typically from an electric motor, to move fluid through a system. The pump’s impeller spins the liquid, creating centrifugal force that pushes the fluid outward and into the discharge pipe. This simple yet effective mechanism ensures consistent fluid movement with minimal effort.

Key Components of Centrifugal Pumps:

- Impeller: The rotating component that generates centrifugal force.

- Casing: Houses the impeller and directs the flow of fluid.

- Suction Pipe: Draws fluid into the pump.

- Discharge Pipe: Expels fluid from the pump into the system.

Advantages of Centrifugal Pumps in Industrial Applications

1. High Efficiency and Performance

Centrifugal pumps are known for their ability to handle large volumes of fluid at high speeds, making them ideal for industrial operations requiring quick and efficient fluid transfer.

Benefits:

- Consistent flow rates.

- High-speed operation.

- Minimal energy consumption.

2. Cost-Effectiveness

One of the primary reasons industries choose centrifugal pumps is their affordability. They have a relatively simple design, which translates to lower manufacturing and maintenance costs.

Cost Benefits:

- Lower initial purchase price.

- Reduced maintenance and repair expenses.

- Energy-efficient operation lowers utility costs.

3. Versatility Across Industries

Centrifugal pumps can handle various fluids, including water, chemicals, and slurries. Their adaptability makes them suitable for numerous industrial applications, from food processing to petrochemicals.

Common Applications:

- Water supply and treatment.

- Chemical manufacturing.

- Oil and gas refineries.

4. Ease of Installation and Maintenance

The straightforward design of centrifugal pumps simplifies both installation and maintenance. With fewer moving parts, the risk of mechanical failure is minimized.

Maintenance Advantages:

- Simple disassembly for cleaning and repairs.

- Availability of spare parts from suppliers like Calama Pumps.

- Lower downtime due to quick servicing.

Factors to Consider When Choosing a Centrifugal Pump

Selecting the right centrifugal pump for your industrial application requires careful evaluation of several factors. Understanding these considerations ensures you get the best performance and longevity from your equipment.

1. Flow Rate Requirements

The flow rate, measured in gallons per minute (GPM) or cubic meters per hour (m³/h), determines how much fluid the pump can move. Matching the pump’s capacity to your operational needs prevents underperformance or overexertion.

How to Assess:

- Calculate your system’s peak demand.

- Consider variations in fluid volume over time.

- Choose a pump with a flow rate slightly above your maximum requirement.

2. Pressure and Head

The pressure the pump needs to generate to move fluid through the system is crucial. Head refers to the height the pump can push the fluid, and it impacts the pump’s efficiency.

Factors to Evaluate:

- Total dynamic head (TDH) of your system.

- Friction losses in piping and fittings.

- Vertical lift and discharge distance.

3. Type of Fluid

The nature of the fluid being pumped affects the pump’s material and design. Viscous, corrosive, or abrasive fluids require specialized impellers and casings.

Fluid Considerations:

- Temperature and chemical composition.

- Viscosity and particle content.

- Compatibility with pump materials.

4. Pump Efficiency

Energy-efficient pumps lower operational costs and reduce environmental impact. Evaluating the pump’s efficiency curve helps determine its performance across various flow rates and pressures.

Efficiency Tips:

- Select pumps with high-efficiency ratings.

- Monitor performance metrics like power consumption.

- Partner with suppliers like Calama Pumps for energy-efficient options.

5. Durability and Construction

Industrial environments demand robust equipment. The pump’s construction material must withstand harsh conditions, including high temperatures and corrosive chemicals.

Material Choices:

- Stainless steel for chemical resistance.

- Cast iron for durability in heavy-duty applications.

- Specialized alloys for high-temperature operations.

6. Supplier Reputation and Support

Choosing a reputable supplier ensures you receive high-quality equipment and reliable after-sales service. Trusted names like Calama Pumps offer expert advice, genuine spare parts, and comprehensive support.

Why Supplier Matters:

- Access to certified and tested equipment.

- Technical support for installation and maintenance.

- Warranty and service agreements.

Why Calama Pumps Recommend Centrifugal Pumps

Calama Pumps has established itself as a leading provider of industrial pumping solutions, and centrifugal pumps remain one of their top recommendations. Their efficiency, cost-effectiveness, and versatility align perfectly with Calama Pumps’ commitment to quality and performance.

Reasons for Recommendation:

- Proven reliability in diverse industrial applications.

- Availability of customizable solutions.

- Strong after-sales support and maintenance services.

Frequently Asked Questions (FAQs)

Why are centrifugal pumps so popular in industrial use?

Their efficiency, affordability, and ability to handle various fluids make them a preferred choice for industrial applications.

What types of fluids can centrifugal pumps handle?

Centrifugal pumps can move water, chemicals, oils, and slurries, making them versatile across industries.

How do I choose the right centrifugal pump for my needs?

Assess flow rate, pressure requirements, fluid type, and system head to select a pump that meets your specifications.

Are centrifugal pumps energy-efficient?

Yes, their high efficiency reduces power consumption, lowering operational costs.

Why trust Calama Pumps for centrifugal pump solutions?

Calama Pumps offers high-quality, efficient centrifugal pumps with expert support and reliable service.

Centrifugal pumps continue to dominate industrial applications due to their efficiency, affordability, and adaptability. By partnering with reputable suppliers like Calama Pumps, businesses ensure they receive high-performance equipment tailored to their specific needs.

Caterories

- No category available.

Subscribe

Subscribe to Our newsletter for free Update every week