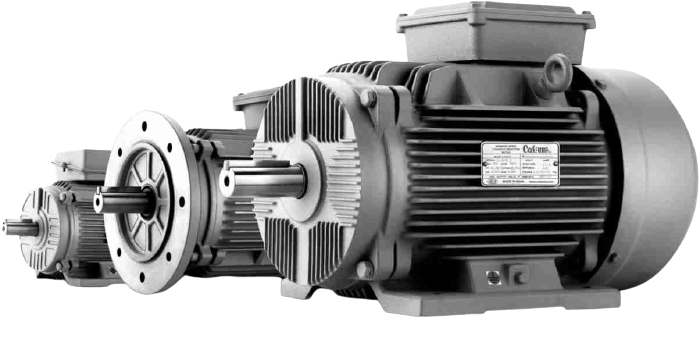

Our premium electric motors combine cutting-edge technology and high-quality components to provide unparalleled performance for a variety of applications. Whether you're in manufacturing, agriculture, transportation, or home automation, our electric motors offer the power, longevity, and dependability you need to stay ahead.

How do Calama electric motors work?

Electric motors operate on the principles of electromagnetism. When an electric current passes through a wire wound around a rotor, it generates a magnetic field. This interacts with a stationary magnetic field, causing the rotor to spin and produce mechanical motion. The speed and torque of the motor can be controlled using different techniques such as variable frequency drives (VFDs) or controllers.

Key Features and Benefits:

- Energy Efficiency:

Engineered to minimize energy consumption, our electric motors are designed to deliver maximum torque while optimizing power usage, resulting in significant energy savings and reduced operational costs over time. - Wide Range of Options:

Our motors are available in a variety of types including AC motors, DC motors, and specialized solutions tailored to your specific needs. Whether you need a low-power motor for light-duty applications or a high-power motor for industrial machinery, we offer a solution for every requirement. - Robust Build Quality:

Constructed with high-grade materials such as aluminum, stainless steel, and cast iron, our electric motors are designed to handle the toughest working environments, including high moisture, temperature fluctuations, and exposure to dust and debris. - Quiet and Smooth Operation:

With advanced balancing techniques and noise-reduction technology, our electric motors are built to operate with minimal noise, ensuring a comfortable working environment in both industrial and residential settings. - Customizable Configurations:

We offer customizable designs, such as motor windings, enclosure types, and voltage ratings, to ensure that you can find the perfect fit for your project. Whether you need high-speed motors for precise applications or high-torque motors for heavy-duty machinery, we can provide tailored solutions. - Low Maintenance Requirements:

Designed for durability and longevity, our electric motors are low-maintenance, reducing downtime and minimizing the need for repairs or replacements. This ensures long-term reliability, helping your operations run smoothly with minimal intervention. - Versatile Applications:

Our electric motors are trusted across various sectors, including: - Industrial Equipment: For machines, pumps, compressors, and fans.

- HVAC Systems: Ideal for ventilation, heating, and cooling solutions.

- Automated Systems: Perfect for robotics, conveyors, and automation lines.

- Renewable Energy: Used in wind turbines, solar tracking systems, and more.

- Residential: Suitable for appliances, garage doors, and water pumps.

- Advanced Control and Integration:

For precise control and optimized operation, our electric motors can be integrated with variable frequency drives (VFDs), controllers, and sensors, giving you the ability to adjust motor speed, torque, and power output based on your application’s real-time demands. - Global Compliance and Certifications:

All of our electric motors meet or exceed the necessary industry standards and certifications for safety, performance, and environmental sustainability. This includes compliance with international standards such as IEC, UL, and CE.

Why Choose Our Electric Motors?

- High-Quality Components: Only the best materials are used to ensure motor efficiency and longevity.

- Superior Customer Support: Our experienced team offers expert advice and custom motor solutions tailored to your needs.

- Reliable Performance: Our motors are designed for continuous operation, ensuring maximum uptime and reduced maintenance.

- Sustainability: By using energy-efficient motors, you're contributing to a greener planet with reduced energy consumption and fewer carbon emissions.

Applications:

- Manufacturing and Industry: Ideal for conveyors, robotic arms, CNC machines, and industrial automation systems.

- Agriculture: Perfect for irrigation pumps, farming equipment, and renewable energy systems such as wind and solar energy applications.

- Transportation: Used in electric vehicles, marine vessels, and other transport systems.

- Home Appliances: Motors that power washing machines, refrigerators, air conditioning units, and more.

- Power Generation: Ideal for use in turbines and backup power systems.

FAQs—Calama Electric Motors

1. What applications can electric motors be used for?

Electric motors are highly versatile and can be used in a wide range of applications, including:

- Industrial: Pumps, fans, compressors, conveyors, and industrial machinery.

- HVAC Systems: Motors for air conditioning, heating, ventilation, and refrigeration.

- Home Appliances: Washing machines, refrigerators, microwaves, and more.

- Transportation: Electric vehicles, electric bikes, and marine applications.

- Renewable Energy: Wind turbines, solar-powered systems, and more.

2. How do I choose the right motor for my application?

Choosing the right motor depends on several factors, including:

- Power Requirements: Determine the voltage, current, and power rating needed for your application.

- Torque and Speed: Consider the torque and speed needed for your operation.

- Environment: Choose motors that can withstand specific environmental conditions (e.g., temperature, moisture, dust).

- Efficiency: Select energy-efficient motors for long-term cost savings.

3. What is the difference between AC and DC motors?

- AC Motors: Use alternating current and are typically used in applications requiring constant speed. They are more common in industrial and household equipment.

- DC Motors: Use direct current and offer better speed control and higher torque at startup. These are ideal for precision applications like robotics or small appliances.

4. What is an energy-efficient motor?

Energy-efficient motors are designed to consume less electricity while providing the same level of performance. They reduce energy costs and are more environmentally friendly by lowering carbon emissions. Motors with high-efficiency ratings are compliant with international energy standards.

5. How long do electric motors last?

The lifespan of an electric motor can vary depending on the type, usage, and maintenance, but most motors can last anywhere from 10 to 20 years or more with proper care. Regular maintenance, such as cleaning, lubricating bearings, and monitoring performance, can help extend the life of the motor.

6. How do I maintain my electric motor?

To ensure the longevity and optimal performance of your electric motor, consider these maintenance practices:

- Regularly clean dust and debris from the motor.

- Inspect bearings, shaft alignment, and couplings.

- Lubricate parts according to manufacturer recommendations.

- Monitor motor performance for any signs of abnormal vibration or temperature fluctuations.

7. Are your electric motors customizable?

Yes! We offer customizable options for many of our electric motors, including modifications to power ratings, voltage configurations, enclosure types, and special materials to suit your specific application needs.

8. What certifications do your electric motors have?

Our electric motors are compliant with industry standards such as:

- CE (European Union): Ensures compliance with safety, health, and environmental protection standards.

- UL (Underwriters Laboratories): Certifies safety and quality.

- IEC (International Electrotechnical Commission): Meets international electrical and safety standards.

9. How can I get technical support or customer service?

Our team of experts is available to assist with any technical or product-related inquiries. You can contact us through our website or customer service hotline, and we’ll provide the guidance you need for selecting, installing, or maintaining your electric motor.

10. Can I use your motors in outdoor environments?

Yes, we offer electric motors with different levels of protection against the elements, such as waterproof or weather-resistant models. Be sure to choose the right motor for your specific environmental conditions, such as extreme temperatures, exposure to moisture, or dusty environments.